- (513) 305-0700

Modern, efficiently designed buildings don’t have too much space, they have just enough. Engineers are often challenged by architectural design to find enough free space to install and maintain all of the required mechanical equipment. Even tougher when you consider the additional space required for accessibility, duct, piping, wiring, on and on.

We in the instrumentation world are looking for nice, long, straight runs of duct and piping so we can achieve accurate and reliable flow measurements.

Instrumentation requires straight runs for two simple reasons.

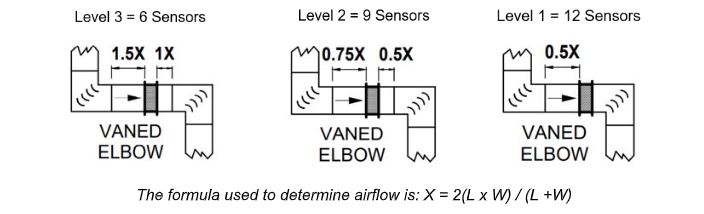

So, what do we do when we require accuracy and or repeatability, but are unable to meet the manufacturers installation guidelines? I’m glad you asked! One thing that we can do with our thermal airflow stations is to increase the density of the sensors, each of which is a sensing point. Consider taking a flow reading in a 36” x 36” section of ductwork. Air Monitor offers three different levels of sensor density, Level 1, Level 2 and Level 3. For this size duct we would offer 12, 9 or 6 sensors. See the impact of the increase in sensor densities as it relates to straight run below.

Contact us to learn more about our available options for minimal straight run including honeycomb air flow straighteners and our new OAM II (Outdoor Airflow Station) that does not require any straight runs for accurate, repeatable flow measurement.

View the cut sheet here.