- (513) 305-0700

Parking garages, office buildings, and other occupied structures must be well ventilated and free from air-borne contaminants. And today’s gas detection systems are critical to monitor conditions and expel the buildup of hazardous fumes.

Gas detection can be complicated, and consulting engineers often turn to the experts to get it right the first time. AEB Technologies (AEB) provides the expertise, experience, and technologies to ensure project success and protect building occupants from hazardous gases.

Monitoring the Ambient Atmosphere

According to Critical Environment Technologies (CET) Sales Manager, North America Region, Ron Sweet, location is critical when it comes to sensor placement.

“Although air monitoring systems are capable of detecting minute particles over wide distances, exactly where they are mounted within the building envelope is critical to ensuring complete coverage,” he said. “Think about an auditorium. That thermostat sitting on a distant wall is monitoring the ambient atmosphere to keep the entire area at a comfortable temperature. This is possible because the ambient atmosphere is in constant motion. Gas detection sensors work on the same premises. To get the highest efficiency it’s best if you can have 360° of air motion around it. Exactly where sensors are located is critical to ensure complete coverage and 100% efficiency.”

Identifying Needs & Solutions

AEB will meet with the contractor or building engineer to review the design drawings and sensor placement. Many important considerations that must be reviewed.

Next, we identify the gases to be monitored. There are many types of gases – toxic, combustible, refrigerants, asphyxiants and compounds such TVOCs and particulates. To help determine the optimum solution we ask questions like:

We’ll work with you to examine plan drawings to identify the number of needed C0 and N02 sensors and their exact locations. We’ll help you to choose the best product for your application. This often includes:

It’s important that the consulting engineer, who needs to approve the project, has confidence in the recommended sensor layout map. We’ll answer any questions and make sure that you fully understand all recommendations.

Installation & Validation

Once the recommendations are accepted, AEB places the order for your customized monitoring systems. CET has factory sequences that are programmed into the system for detecting gas build up and operating the ventilation system to dilute through ventilation the buildup of toxic or combustible gas. However, if the application requires a specific sequence of operations, the sensors can be programmed accordingly.

All equipment is shipped configured, calibrated, and ready to install and put into service. The only step needed is physical installation and powerup. There are only a handful of manufacturers in this industry who offer this.

All equipment is shipped configured, calibrated, and ready to install and put into service. The only step needed is physical installation and powerup. There are only a handful of manufacturers in this industry who offer this.

“We can provide this simply because of the amount of time we’ve been in the industry,” said Sweet. “We’ve seen how when equipment leaves the factory, there’s a potential for things to go downhill. Mechanical contractors are used to installing fans, diffusers, and simple HVAC products. A gas detection system isn’t something they install every day. This simplifies installation for the contractor and limits the amount of support we need to provide remotely.”

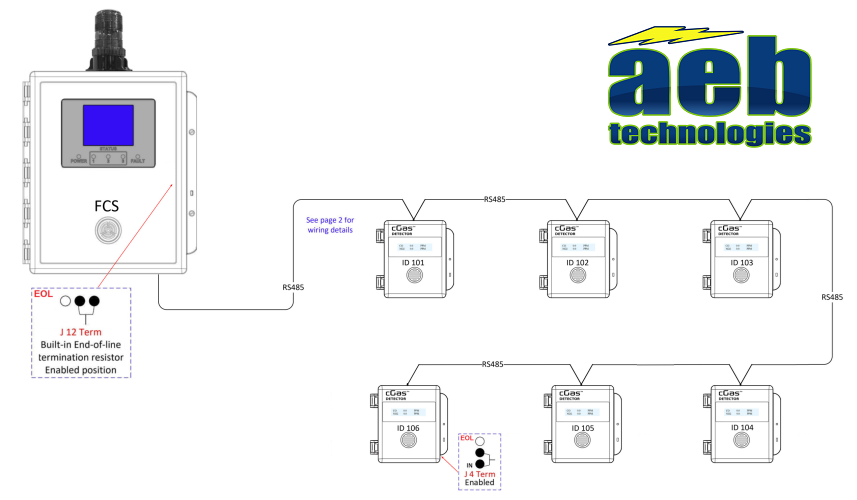

To back this up, CET includes the wiring diagram. From the overall layout to the complete wiring details including fan connections. AEB can supervise and test installation to be sure that the gas detection system is properly installed and working as designed.

Every Step of the Way

With any equipment proper placement is important – with sensors it’s critical. Relocating equipment adds needless time and expense to your project. We’ll help you get it right the first time. Send us a picture or layout of your project plan and we’ll identify optimal sensor placement. We can even go on site to make recommendations and approve installation. Of course, this service is provided at no cost.

With any equipment proper placement is important – with sensors it’s critical. Relocating equipment adds needless time and expense to your project. We’ll help you get it right the first time. Send us a picture or layout of your project plan and we’ll identify optimal sensor placement. We can even go on site to make recommendations and approve installation. Of course, this service is provided at no cost.