- (513) 305-0700

Refrigerant gases are literally the lifeblood of today’s air conditioning, refrigeration, and freezing technologies. Under controlled and monitored conditions these gases are safe and efficient. However, if not closely monitored and allowed to escape into the atmosphere, they can be extremely hazardous to both personnel and our environment.

To help ensure safety, ASHRAE (The American Society of Heating, Refrigerating and Air-Conditioning Engineers) mandates that each refrigerant machinery room be monitored for leaks. Specifically, ASHRAE section 8.11.2.1 states: “Each refrigerating machinery room shall contain a detector, located in an area where refrigerant from a leak will concentrate, that actuates an alarm and mechanical ventilation in accordance with Section 8.11.4 at a value not greater than the corresponding TLV-TWA (or toxicity measure consistent there with)…”

In addition to monitoring, further steps should be taken to ensure the safety of building occupants, maintenance personnel, and early responders. These include, among other precautions, external alarms, and the availability of self-contained breathing apparatus (SCBA).

Reliable refrigerant gas monitoring is critical. Fortunately, there proven technologies available to building contractors and owners to detect and measure leaks.

Risks to Health & Environment

Leaking refrigerant gases pose a serious threat to our physical and environmental health.

Risks to Humans

Human health risks range from mild discomfort to life-threatening illness. Less severe reactions to gas poisoning include headache, nausea, shortness of breath, dizziness, coughing, vomiting, loss of coordination, and confusion. Skin rashes are another symptom, particularly for those with sensitive skin and direct contact can cause a chemical burn or frostbite.

Severe refrigerant gas poisoning can result in vomiting blood, breathing difficulties, loss of consciousness, bleeding or fluid buildup in the lungs, seizure, a burning sensation in the windpipe, irregular heartbeat, coma, or sudden death. Loss of consciousness and eventual asphyxiation from Oxygen deprivation can occur when refrigerant gas displaces the Oxygen content in closed mechanical room air.

Environmental Risks

Similarly, the leakage of refrigerant gases effects the environment. Gases that leak into the atmosphere can contribute to ozone depletion and global warming. Indirectly, refrigeration and air conditioning systems consume energy, which raises CO2 emissions contributing to global warming.

Choices are always being made by chiller manufacturers regarding cost, availability, effectiveness, public safety, and environmental impacts. For example, because of their non-flammability and non-toxicity, refrigerant gasses such as haloalkanes, chlorofluorocarbons and hydrochlorofluorocarbons (particularly CFC-11 and CFC-12) made them preferred choices for many years. However, their atmospheric stability made these gases a threat to the ozone layer. Consequently, these refrigerants were replaced with HFCs and PFCs, especially HFC-134a, which are not-ozone depleting. Yet, these gasses still pose threats to global warming and are being replaced by more environmentally friendly refrigerants.

Newer refrigerants are safer for the environment; but create concerns over toxicity and flammability. Some of today’s more popular refrigerants include:

(Note: R-513a and R-514a are the current replacements for R-134a and R-123 respectively.)

The Financial Impact of Leakage

In addition to presenting health and environmental risks, refrigerant leakage will have a financial impact on the business. The loss of refrigerant may cause the system to struggle to produce adequate cooling preventing buildings from reaching and maintaining desired temperatures. This not only causes the system to work harder; but will also increase monthly energy bills. An undercharged system uses significantly more energy.

Of course, there are additional expenses associated with the loss of refrigerant. These include costs such as labor to locate and repair the leak and re-charge the system. It can cost thousands of dollars to repair and replace the refrigerant in a commercial or industrial chiller. Finally, there is a cost related to system downtime. While this will vary significantly with system and application, the cost can be significant.

Refrigerant Gas Monitoring Solutions

Ceramic Metal Oxide Semiconductor

Invented at Bell Labs in 1959, Metal Oxide Semiconductor technology has been around for more than sixty years. Since that time, billions of dollars have been invested in development, related technology, and instrumentation. Ceramic Metal Oxide Semiconductors (CMOS) are today a popular refrigerant gas monitoring solution. CMOS sensors will also detect gases, such as carbon monoxide, sulfur dioxide, hydrogen sulfide, and ammonia.

Within these semiconductors, sensing material is printed on an element with a heater formed on the reverse side which heats the material to several hundred degrees C. The flow of electricity inside the sensing material is determined by the number of free electrons. When the air is clean, oxygen is absorbed on the sensing material. This attracts free electrons resulting in an increase in the sensor resistance and less flow of electrons inside the sensing material.

In the presence of gases, the gas reacts with absorbed oxygen. This causes the electrons held by absorbed oxygen to be released into the sensing material. As a result, sensor resistance decreases allowing more current. As the concentration of gas increases, sensor resistance decreases further, allowing even greater current.

Advantages to this approach are that it is generally reliable, robust, cost effectiveness, relatively long-lasting, scalable, and deliver quick response times. Employed in a variety of roles and industries, these sensors are used extensively to measure and monitor trace amounts of carbon monoxide and nitrogen dioxide.

The biggest downside to CMOS monitoring is that the technology is not gas specific. Because it is cross-sensitive to many gases sensors are known to create false alarms in environments that contain gasoline, diesel, and propane exhaust or solvents, cleansers, and Volatile Organic Compounds (VOC). Disruptions associated with false readings can be time-consuming, costly, and distract building maintenance staff from other duties. Still, despite these limitations, CMOS remains a viable gas monitoring solution for meeting code requirements within a limited budget.

Inaccuracies of the sensor elements can lead to non-reproducibility of the gas attributes. CMOS calibration is therefore critical. Although the signal patterns of the various sensor elements of a production batch are quite similar, each sensor element must be calibrated to yield high analytic performance.

The importance of sensor calibration cannot be overstated. Regular calibration is the best and only sustainable method for maintaining gas monitoring system accuracy. Recalibration is not only recommended; but required to meet safety, reliability, and accuracy standards

Infrared

Infrared technology can also be used to monitor refrigerant gas leaks. Discovered in the 1800s by Alexander Graham Bell, infrared technology took a quantum leap forward in 1929 when the infrared-sensitive electronic television camera was invented. In 1947, the first American thermographic cameras were developed for military use.

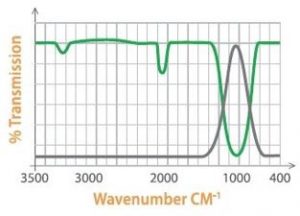

Infrared gas detection uses infrared light to detect the presence of gas. When exposed to the infrared light, the gas absorbs some of the light’s energy. Because gases absorb light energy at different wavelengths, this allows gases to be identified by measuring the absorption of light at specific wavelengths. Unlike CMOS, infrared monitoring technology is gas specific and extremely accurate.

Infrared technology comes in two forms: Absorptive (NDIR, non-dispersive infrared) and Photoacoustic.

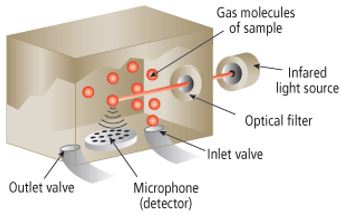

Photoacoustic infrared measures an audible pulse that is generated by the refrigerant being exposed to the light. Pressure is generated inside the sealed chamber by the movement of gas molecules as they absorb the light energy. As pressure increases it is detected by a microphone inside the monitor. The extent of the pressure indicates the concentration of the gas present. A stronger pulse indicates that more gas is present. The sensitive microphone inside the monitor is sensitive and can detect even the lowest levels of gas.

What’s the Best Option?

When selecting refrigerant monitors, engineers must consider the exposure limits of the refrigerant, the mechanical room functionality and the long-term maintenance (including ongoing service) versus upfront cost.

From a pure price perspective, CMOS sensors are the least expensive option followed by Absorptive Infrared (for systems with minimal sensors) and finally Photoacoustic Infrared. An important fact to consider is that both CMOS and NDIR Systems have a higher cost per sensing point than Photoacoustic Infrared. This is due to their technology being located at the point of sensing rather than in the electronics cabinet as with Photoacoustic. Systems with greater than 3 sensing points (some refrigerants require 2 per chiller) will quickly erode this advantage and Photoacoustic Infrared technology will gain both price and performance advantage.

While the choice is yours, we highly recommend Photoacoustic Infrared Systems. We base this on their ability to provide the highest level of protection, the earliest possible alerts, the lowest required maintenance and the greatest flexibility of all of today’s available technologies.

Need Help?

AEB Technologies is here to help you make informed decisions. We can help determine the optimal refrigerant gas monitoring system for your specific application and budget. We work closely with leading HVAC manufacturers and our Instrumentation and Controls focused line card includes some of the industry’s best metering, monitoring and equipment solutions for energy-efficient campus and building management.

Recalibration is vital to sensor performance and accuracy; and AEB is your partner for expert calibration. Our calibration services keep your gas monitoring system operating efficiently and aligned with the exact specifications of its manufacturer.

We are happy to help with any questions or comments that you may have about our manufacturers or equipment. Contact us here.