Parking garages might seem like a simple, low-tech construction; and comparatively speaking most are. However, because the structure is meant to house automobiles and similar gasoline-powered vehicles, there are related hazards that must be accounted for. So, when Ohio’s Dayton Public Library wanted to ensure the safety of patrons in its new multi-story parking garage, AEB Technologies stepped in to help.

Dangerous Fumes

Carbon Monoxide (CO) and Nitrogen Dioxide (NO2) are two of the most abundant and dangerous airborne contaminants found in parking structures. Serious life-threatening health risks occur when the accumulation of one or more of these gasses exceeds acceptable levels. Consequently air quality must be continually and reliably monitored. When toxins accumulate – quick response is nothing short of critical.

Because of the importance to accurately monitor air quality and provide high-level alerts, the building controls contractor was prepared to make a significant investment to ensure the safety of the garage patrons. What they would find, however, was a more reliable and cost-effective solution.

Air Monitoring

The contractor needed a system that would continually and reliably:

- Sample the air throughout all levels and areas of the structure

- Automatically initiate the start-up of fans and/or other air moving equipment as needed

- Activate sirens and/or other warning sources if dangerous levels persisted

According to project specifications, a pump-driven sequential sampling system consisting of twelve sensors would be installed to draw and sample air. Two possible manufacturers were listed as options for supplying such a system. In the end however, neither option would prove to offer the optimum solution.

A Linear Approach?

AEB recognized that such a system was neither the most effective nor cost-effective solution. The company’s Vice President, John Downing had a better solution in mind.

“Sequential air sampling systems are inherently slow and costly,” explained Downing. “The linear aspect of such systems means that the sampling cycle is measured in terms of minutes. And when dealing with CO or NO2, every second is critical.”

Furthermore the proposed air monitoring system was dependent on pumps which, with their moving parts, require frequent maintenance and will eventually fail.

A More Reliable, Cost-Effective Solution

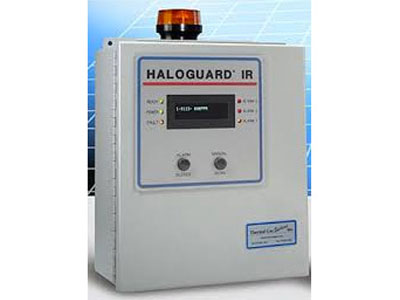

AEB proposed a system from the gas detection experts, Critical Environmental Technology (CET). Founded in 1995, CET is a leading global manufacturer of gas detection systems, including self-contained systems, controllers and transmitters, and Indoor Air Quality (IAQ) monitors.

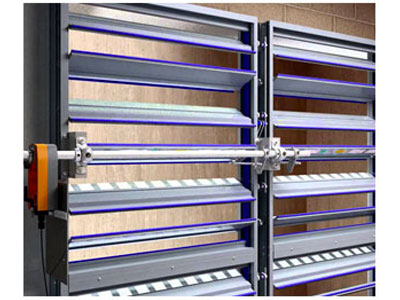

The point-to-point system utilizes an open BACnet control system integrated through a building control dashboard. And, because the electric/battery back-up powered system does not rely on a pump, it is reliable and requires little maintenance. Most importantly, the non-sequential system provides instantaneous air quality readings.

What’s more, the CET air monitoring system was installed at a cost significantly less than the sequential system in the original building specifications. This equated to a cost savings of approximately $15,000 to $20,000 on the project.

Results

Today the Dayton Public Library is home to a modern parking garage offering safe and reliable air monitoring. Thanks to AEB and CET, building owners and patrons alike can rest assured knowing that the quality of air within the structure is being continually and effectively monitored.