While ventilation is important in all commercial and residential buildings, it is especially critical for healthcare facilities. Reliably consistent airflow and related air pressure helps to maintain a clean and healthy environment. And good ventilation improves air quality and helps to prevent the spread of airborne allergens and related illnesses.

While ventilation is important in all commercial and residential buildings, it is especially critical for healthcare facilities. Reliably consistent airflow and related air pressure helps to maintain a clean and healthy environment. And good ventilation improves air quality and helps to prevent the spread of airborne allergens and related illnesses.

As the second largest health system in Ohio and the state’s fourth-largest employer, Mercy Health operates more than 250 healthcare organizations throughout Ohio and Kentucky. General Contractor, Peck, Hanniford & Briggs was hired to oversee construction of Mercy Health’s 60-bed, state-of-the-art hospital and new medical office building in the Mason, Ohio area. The facility will offer a comprehensive range of high-quality healthcare services for residents throughout several surrounding communities.

Duct Work Challenges

Straight runs of ductwork allow for the flow profile to fully develop where it can be measured accurately. However, rooftop HVAC units are often designed with little or no straight run duct work which creates challenges for many airflow measurement systems. In this case the building’s air handling unit design included no straight runs. Consequently, an alternative air measurement solution was needed.

Straight runs of ductwork allow for the flow profile to fully develop where it can be measured accurately. However, rooftop HVAC units are often designed with little or no straight run duct work which creates challenges for many airflow measurement systems. In this case the building’s air handling unit design included no straight runs. Consequently, an alternative air measurement solution was needed.

Originally, a thermal-based air flow solution was being considered. However, this would require the fabrication of a 3’+ long spool piece and rain hood that would be attached to each of the seven (7) air handling units. The addition would be required to protect the airflow from the elements and to provide the straight runs that are required by the manufacturer for performance.

Additionally thermal flow measurement technologies do not perform as designed when they are exposed to elements such as rain, snow, or condensing moisture. Installing them in this manner in an outside AHU is asking for potential measurement issues. All said and done, this solution could not only affect performance and add unnecessary costs but would also negatively impact the building’s aesthetics.

The AEB Solution

With a reputation for delivering results, AEB was contacted to see if another solution was available. Because a thermal solution had already been proposed and was less than ideal, the company recommended Air Monitor Corporation’s static pressure OAM II Outdoor Airflow Measurement System. Standard equipment costs and installation for the OAM II are similar to that of a thermal probe array.

With a reputation for delivering results, AEB was contacted to see if another solution was available. Because a thermal solution had already been proposed and was less than ideal, the company recommended Air Monitor Corporation’s static pressure OAM II Outdoor Airflow Measurement System. Standard equipment costs and installation for the OAM II are similar to that of a thermal probe array.

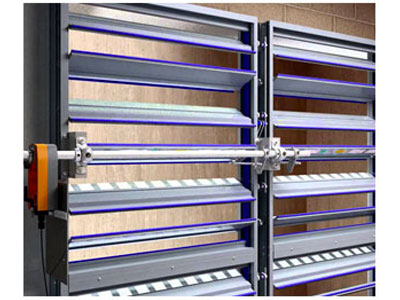

Designed for outdoor applications, the innovative system is remarkably resistant to effects of moisture, dust, debris, shifting wind loads and gusts while providing airflow measurement accuracy to within ±5% of rate, with AMCA certified ZERO straight run requirements. For this application the system consisted of the OAM II Transmitter with stainless steel uni-sensors that could be directly installed into the louver in the air handling units. This solution provided excellent airflow measurement, reduced cost, and installation time as well as minimal impact on building aesthetics.

From measurement and quoting to installation, balancing, testing and sign-off, AEB worked with Peck, Hanniford & Briggs, Johnson Controls, and Heapy Engineering every step of the way.

Results

With a product specifically designed for OA applications, the client is reaping all the benefits of this more durable and lower maintenance solution. While more reliable airflow readings and better building aesthetics are noteworthy, the biggest advantage was in money saved during installation.

Based upon the additional required materials and labor for an installation with thermal probes, estimated cost savings are from $5000 to $7500 for each application. This includes a 36” spool piece for each of these large opening sizes (9’ x 9’) which provided some straight run (although still not meeting manufacturers guidelines), a rain hood or other equipment/materials to protect equipment from the environment and improve aesthetics, as well as mechanical installation and painting of these components. With a total of 6 applications the estimated installation savings range from $30,000 – $45,000.

Few things in this world are as important as the planet itself. And at AEB we’re proud to do our part. This past year, with the help of our customers, AEB planted 379 trees through the organization

Few things in this world are as important as the planet itself. And at AEB we’re proud to do our part. This past year, with the help of our customers, AEB planted 379 trees through the organization

Here, AEB President, Joseph Moore is providing the

Here, AEB President, Joseph Moore is providing the