Chlorine gas, a pale yellow-green substance with a pungent odor, has been widely used since its discovery in 1774. It plays a crucial role in various industries, such as water purification, manufacturing, and chemical production. Despite its utility, chlorine gas poses significant dangers when leaked, affecting human health, the environment, and industrial processes.

Health Risks

Acute Exposure

Acute exposure to chlorine gas can lead to severe health issues. When inhaled, chlorine reacts with moisture in the respiratory tract to form hydrochloric acid and hypochlorous acid, both of which can damage tissue. This can result in symptoms ranging from mild irritation to severe respiratory distress, depending on the concentration and duration of exposure.

- Low Concentrations (1-3 ppm): At these levels, chlorine can cause irritation of the eyes, nose, and throat. Symptoms may include tearing, coughing, and a burning sensation in the throat.

- Moderate Concentrations (5-15 ppm): Exposure to moderate concentrations can result in difficulty breathing, chest tightness, and pulmonary edema, which is the accumulation of fluid in the lungs. This can be life-threatening if not promptly treated.

- High Concentrations (>30 ppm): High levels of chlorine exposure can lead to acute lung injury, suffocation, and death. Victims may experience symptoms such as severe coughing, wheezing, and shortness of breath.

Chronic Exposure

Chronic exposure to lower levels of chlorine gas can lead to long-term health effects. Repeated exposure, even at low concentrations, can cause persistent respiratory problems, such as chronic bronchitis, asthma, and other pulmonary conditions. Long-term exposure is also linked to eye and skin irritation, with the potential for lasting damage to these tissues.

Environmental Impact

Chlorine gas leaks pose substantial risks to the environment. When released into the atmosphere, chlorine gas can react with water vapor to form hydrochloric acid, contributing to acid rain. Acid rain can harm aquatic ecosystems, soil, vegetation, and infrastructure, leading to widespread ecological damage.

Additionally, chlorine can react with organic compounds in the environment, producing toxic byproducts like dioxins and chlorinated hydrocarbons. These compounds can persist in the environment and bioaccumulate in the food chain, posing a long-term threat to wildlife and human health.

Industrial Hazards

In industrial settings, chlorine gas leaks can disrupt operations and pose hazards to workers. Chlorine is often stored and used in large quantities under pressure, and leaks can occur due to equipment failure, improper handling, or accidents. In chemical manufacturing and water treatment plants, for instance, chlorine leaks can lead to fires or explosions if the gas comes into contact with flammable materials.

The presence of chlorine gas can also necessitate evacuation and decontamination procedures, halting production and leading to significant economic losses. Furthermore, the cleanup of chlorine leaks requires specialized equipment and trained personnel, adding to the complexity and cost of managing such incidents.

Preventive Measures

Preventing chlorine gas leaks requires a comprehensive approach that includes proper storage, handling, and maintenance protocols. Key preventive measures include:

- Regular Inspection and Maintenance: Ensuring that storage tanks, pipelines, and valves are regularly inspected and maintained can help identify and rectify potential leak sources before they become critical.

- Training and Safety Protocols: Workers handling chlorine should be well-trained in safety procedures and emergency response. Personal protective equipment (PPE) should be readily available and used appropriately.

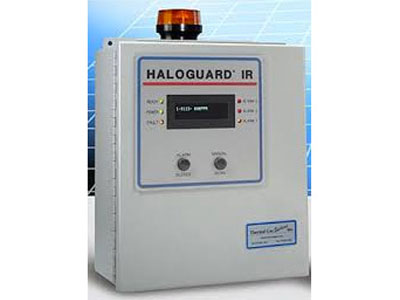

- Leak Detection Systems: Installing advanced leak detection systems can provide early warnings of chlorine releases, allowing for swift response to mitigate risks.

Emergency Response

In the event of a chlorine gas leak, prompt and effective emergency response is crucial to minimize harm. Evacuation of affected areas, provision of medical treatment to exposed individuals, and containment of the leak are essential steps. Emergency responders should use appropriate PPE and follow established protocols for dealing with hazardous gas releases.

Conclusion

Chlorine gas, while valuable in many applications, poses significant dangers when leaked. The health risks to humans, environmental impact, and industrial hazards associated with chlorine gas leaks underscore the need for stringent safety measures and effective emergency response strategies. By understanding and addressing these risks, we can better protect public health, the environment, and industrial integrity from the dangers of chlorine gas leaks.

AEB and Critical Environment Technologies can help you monitor for chlorine gas leaks. Contact us to learn more.

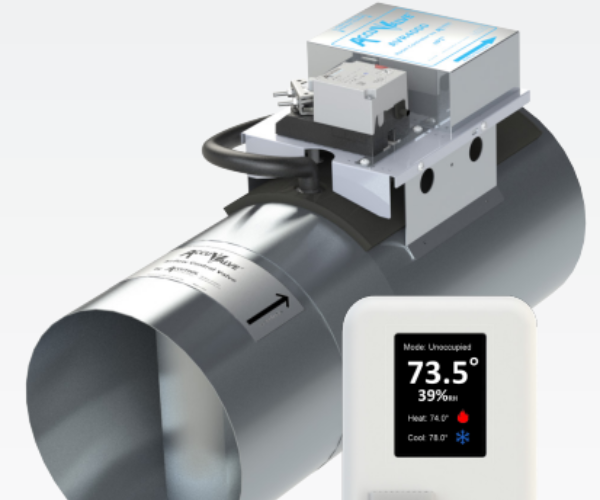

Straight runs of ductwork allow for the flow profile to fully develop where it can be measured accurately. However, rooftop HVAC units are often designed with little or no straight run duct work which creates challenges for many airflow measurement systems. In this case the building’s air handling unit design included no straight runs. Consequently, an alternative air measurement solution was needed.

Straight runs of ductwork allow for the flow profile to fully develop where it can be measured accurately. However, rooftop HVAC units are often designed with little or no straight run duct work which creates challenges for many airflow measurement systems. In this case the building’s air handling unit design included no straight runs. Consequently, an alternative air measurement solution was needed. With a reputation for delivering results, AEB was contacted to see if another solution was available. Because a thermal solution had already been proposed and was less than ideal, the company recommended Air Monitor Corporation’s static pressure

With a reputation for delivering results, AEB was contacted to see if another solution was available. Because a thermal solution had already been proposed and was less than ideal, the company recommended Air Monitor Corporation’s static pressure  Few things in this world are as important as the planet itself. And at AEB we’re proud to do our part. This past year, with the help of our customers, AEB planted 379 trees through the organization

Few things in this world are as important as the planet itself. And at AEB we’re proud to do our part. This past year, with the help of our customers, AEB planted 379 trees through the organization

Here, AEB President, Joseph Moore is providing the

Here, AEB President, Joseph Moore is providing the