Accurate and reliable temperature control is important in any building complex as even minor variances can result in uncomfortable working conditions and excessive energy costs. But when such issues affect hospitals or other types of wellness centers, problems are more than a minor inconvenience. Heating and cooling inefficiencies have a direct bearing on the comfort, health and wellbeing of patients and visitors alike. Additionally, energy costs associated with the inefficient heating/cooling of such massive facilities can quickly add up. So when HVAC control and reliability became a problem at one of the country’s most respected Ohio-based hospitals, AEB and TAMCO stepped in to help.

Accurate and reliable temperature control is important in any building complex as even minor variances can result in uncomfortable working conditions and excessive energy costs. But when such issues affect hospitals or other types of wellness centers, problems are more than a minor inconvenience. Heating and cooling inefficiencies have a direct bearing on the comfort, health and wellbeing of patients and visitors alike. Additionally, energy costs associated with the inefficient heating/cooling of such massive facilities can quickly add up. So when HVAC control and reliability became a problem at one of the country’s most respected Ohio-based hospitals, AEB and TAMCO stepped in to help.

Challenges

Because the facility’s aging air handling system was becoming increasingly unreliable and inefficient, wild temperature variations of anywhere from 8 to 15 degrees off set-point were the norm. This resulted in:

- Noticeably uncomfortable conditions for hospital patients, staff and visitors

- Continuous adjustments to controls and equipment by maintenance staff

- Excessive heating/cooling costs

Not only were energy and money being wasted; but the facility’s maintenance staff was constantly being called in during off hours or taken away from other duties to make adjustments to the control units and dampers. And so, when an opportunity to upgrade the dampers arose, the hospital knew exactly who they would turn to for the solution.

Air Leakage

It is not uncommon for outside air handling systems to experience some level of leakage. But as equipment ages, gaps develop creating leaks or allowing outside air to invade the system. In a relatively short period of time this loss of hot or cold air will become exponentially greater further straining equipment and resources while taking a toll on energy cost. HVAC problems are not uncommon in older large buildings and have a detrimental and unrecoverable cost to the bottom line of any company.

“Air drawn from the outside must be conditioned prior to circulation; and this costs money,” explained AEB Technologies President, Joseph Moore. “Some estimates put this cost at $5 per cubic foot. Now, multiply that by the size of today’s sprawling facilities and you can see why companies are taking air handling equipment upgrades very seriously.” Specializing in commercial HVAC instrumentation and controls, AEB is an Ohio-based company representing market-leading technologies essential to the design of today’s high performance building designs.

A typical damper in need of replacement may experience a leak rate of somewhere in the neighborhood of 150 or so cubic feet per minute. Multiply this by just a 3’ by 3’ foot opening and the result will be 1,350 cfm of leakage. At a square foot cost of $5, that’s nearly $7,000 of savings that a reliable damper can deliver. While this is certainly significant, AEB has seen even greater energy savings.

“There was a recent example of a damper in Chicago leaking at a rate of 230 cubic foot per minute per square foot. Basically the broken damper was stuck to an open position. This 5’ by 5’ opening resulted in 5750 cfm of leakage or about $28,750 additional energy cost. Regardless of the size of the facility, it’s not hard to see the quick payback of a damper system upgrade.”

“A building’s air handling system is only as strong as its weakest link,” concluded Moore. “While dampers and actuators may not represent the same level of investment as rotating equipment, for example, they can quickly negate the efficient operation of the entire system when not functioning properly. When you consider wasted energy costs, quality dampers are clearly worth the investment.”

New TAMCO Dampers

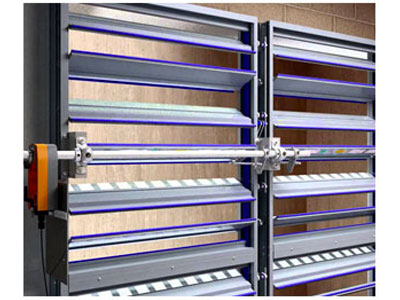

AEB stepped in to bid on a project to retrofit the hospital facility with new dampers. TAMCO low-leakage airfoil blade dampers are aluminum constructed and completely maintenance-free for 20 years. “TAMCO certainly has a good reputation for quality and we’ve always had good experience with their dampers,” said the hospital’s facility manager. “They seal up tight with precise and smooth functionality. For us the choice was a no-brainer.”

Measurable Results

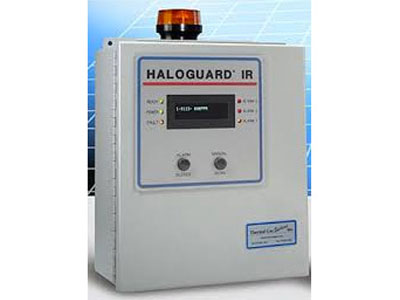

Today, following renovation, uncontrollable temperature swings are a thing of the past at this hospital. “The difference is nothing short of incredible,” said the client. “Today with our pulse DDC (Direct Digital Control) system HVAC functionality is automated and reliable. We set a temperature and know with confidence that throughout our facilities will be within plus or minus 1/10 of a degree.”

Aside from the obvious comfort improvements, the new damper system was delivering significant savings in other areas. In addition to lower energy costs, cost-savings can also be tied to manpower. “Because of the reliable performance of the new tightly sealing TAMCO units we no longer waste time, money and resources continually making adjustments to the dampers,” explained the client. “This allows us to focus our resources and attention in other areas.”

And what was the client’s experience with AEB? “AEB was extremely professional and responsive throughout the entire project. As an example, because of a contractor error one of the damper units needed to be remade. AEB worked to get the replacement unit turned around very quickly.”

Accurate and reliable temperature control is important in any building complex as even minor variances can result in uncomfortable working conditions and excessive energy costs. But when such issues affect hospitals or other types of wellness centers, problems are more than a minor inconvenience. Heating and cooling inefficiencies have a direct bearing on the comfort, health and wellbeing of patients and visitors alike. Additionally, energy costs associated with the inefficient heating/cooling of such massive facilities can quickly add up. So when HVAC control and reliability became a problem at one of the country’s most respected Ohio-based hospitals, AEB and TAMCO stepped in to help.

Accurate and reliable temperature control is important in any building complex as even minor variances can result in uncomfortable working conditions and excessive energy costs. But when such issues affect hospitals or other types of wellness centers, problems are more than a minor inconvenience. Heating and cooling inefficiencies have a direct bearing on the comfort, health and wellbeing of patients and visitors alike. Additionally, energy costs associated with the inefficient heating/cooling of such massive facilities can quickly add up. So when HVAC control and reliability became a problem at one of the country’s most respected Ohio-based hospitals, AEB and TAMCO stepped in to help.